VINTAGE RESTORATION

Vintage restoration is by far, the most difficult category of tune and repair. Very few shops in the country will even take on a board beyond ten or twenty years old. However, there are some awesome pieces of history that deserve to be resurrected. Due to the level of difficulty on these projects, there is a minimum starting price of $150 for work on any board made prior to 2010. These projects also have considerably longer timelines for completion, and will be lower priority than current boards in active use. Below are some examples of various vintage restorations and pricing for specific projects.

Please note, all vintage boards have different needs and various levels of resurrection capability. These examples are intended to be guidelines, and pricing is subject to vary based on your specific project needs and how much I want to do the project.

Paint Removal and Re-Painting

Paint removal is one of the hardest things to do with vintage restoration. Some paint can be very brittle and/or sun damaged. There can be several layers of paint coatings and sometimes there is missing chunks of original graphic that need to be replaced. You rarely know what you're in for until the first bit of the original graphic shows through.

The price depends on three things:

1) If any solvents have already been used in a previous removal attempt

2) How many paint layers exist/how thick is the paint

3) If any repainting is needed

4) How long the project takes to complete

This particular paint removal job was fairly simple. The owner had already removed a significant amount of the paint themselves, and hired me to get it to the finish line to avoid damaging the original graphic any further. The paint was brittle, especially around the eyes of the skeleton, but still workable without losing too much.

Time for completion: 3 hours

Material cost: $22

Total cost: $200

This board had missing paint chunks as well as missing texture from the flowertop print. Epoxy was added to create the texture in the missing areas. The paint was color matched and touched up to fill in the missing graphic.

Time for completion: 3 hours

Material Cost: $7

Basic tune: $60

Total cost: $250

Time for Completion: 12 Hours

Material Cost: $22

Full Tune: $75

TOTAL COST: $450

This was a big project. Super rare board, inconsistent color fading all over the place, and paint chips around the whole thing. Because of the color fading, it is nearly impossible to add touch up paint in spot treatment. It requires doing large sections and blending entire areas of paint. The rust was also removed from the inserts and the base was full tuned.

This board took a lot more labor hours than expected, and I didn't feel comfortable charging my normal rate. But I am stoked on how it turned out. This board will looks mint.

Not all re-paint projects are gnarly and scary. Here is a simple one that just had one spot of touch up needed blending. This board was in killer shape otherwise.

To start it off, the paint was matched with the closest stock color possible. After that first coat, a second and third layer got added on top with a little more gray in it to minimize the visibility for this touchup. The final product blended quite well.

Time for Completion: 1 Hour

Full Tune: $75

TOTAL COST: $150 (MIN)

Here is another easier paint removal project that did not require any repainting. There was just a few spots with heavy paint, and the rest of the board just had a light paint mist. Once all the thicker paint was removed, the entire perimeter was given a light solvent scrub to remove that mist and even the sheen for the entire board. Once cleaned up, the board was clear coated with the appropriate amount of gloss and that was a wrap.

Time for Completion: 2 Hours

Material Cost: $22

TOTAL COST: $150 (MIN)

Large Delaminations

Some of these old boards have massive delaminations. For old Libs, there's usually separation around all four contact points. In some cases, that separation goes around the entire perimeter. There is two ways to go about fixing this. Option one, is to keep the original material intact. First, the rust under the base needs to be removed and the delam needs to be "chased" to the nearest point of solid bonding. These sections can get big, and the repair isn't invisible, but it preserves the board in the most original condition possible. the second option, is to strip the entire base, and the entire perimeter of edge off the board. The board shape can be traced onto a new base sheet, with brand new edges installed, and the board can be vacuum pressed with that new material. Option two is incredibly expensive, but can be worth it on high value collectibles.

This board was in rough shape. It had separated edges popping out on all four corners, and massive delalmination sections around the nose and tail. There was also a ton of rust on the edge material, underneath the base. All that rust had to be removed. Then the edges got bent back into position and relaminated. It was full tuned from there.

The material got a bit worn where the rust removal took place, but the finished product was well worth that sacrifice.

Rust Removal: $60

Relamination: $150

Material Cost: $15

Full Tune: $75

TOTAL COST: $300

The delamination on this definitely large, but it had such a clean separation that the repair was actually easier than expected. There were a couple chunks of topsheet missing that got filled with clear epoxy, but other than those spots, this one came out clean.

Relamination: $90

Basic Tune: $60

TOTAL COST: $150 (MIN)

Re-Base

Sometimes a board’s base is simply too far gone. In 99% of cases, boards in this condition aren’t worth repairing and should be retired. That said, saving them is possible. In rare cases—when a board has deep personal value—the entire base can be removed and replaced. This is not a service I typically offer. This restoration like this takes an enormous amount of labor, and if priced accordingly would fall in the $1-2k range.

Will I do it again? Probably not. But it can be done.

This example had a completely destroyed base and edges, likely from decades of sun exposure. The P-tex was so degraded it was breaking off in chunks. The process involves stripping the board down to the core, creating a new camber mold, and vacuum pressing the board with new f fiberglass, base material, and edges. The result is essentially a brand-new snowboard built around the core of a 30-year-old deck.

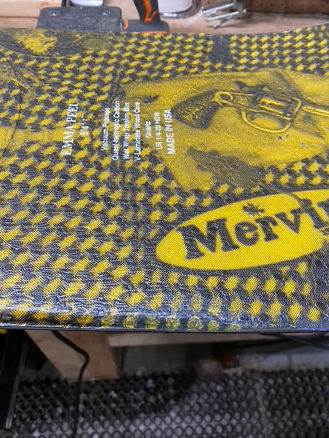

Here's an even cooler one I did with an old Emma Peel (not the same one shown in the previous example). The base was so badly bubbled that there was no fixing it with the original material. This sequence shows the re-basing process a little better. You can see how the custom mold is made and how the vacuum press process works. I also added a modern insert pack on this one, so the board could be ridable again with up to date bindings. New fiberglass, new edge, new base and new inserts.

It's still too much work to offer as a service.. but it's too cool to not show it off here.

External Shopwork Correction

I see a lot of boards that have repair attempts before they are brought to me—by shops without real repair experience or by DIY attempts that went sideways. The intentions are good, but improper repairs can cause lasting damage and are often difficult, or impossible, to correct later. Like a bad tattoo: once it’s there, it’s hard to fix and sometimes impossible to fully erase. Snowboards are complex, and not every shop understands how to fix them. The board shown here is a perfect example of what can happen when experience is missing. I did plenty of other work on this board too—but let's focus on this one section for the purposes of the example.

This board got the works. Delamination repair on all four corners, multiple t-nut replacements, t-nut rust removal and old epoxy removal to start.

It also had that big'ol nasty repair, which was a whole project by itself. The first stage was to carefully grind out that old epoxy. Once that was gone, there was a significant depth in that spot that needed to be rebuilt with epoxy. Next, that cured epoxy was then dremeled with a detail bit to create the follow top texture and blend the repair with the natural texture of the board. After that, the whole area got re-painted and blended into the board. It also got a ton of p-tex work, new p-tex caps over the t-nuts, and a full tune. Overall, this extremely rare colorway "RAD RICK" went from a 3/10 to an 8/10 condition.

As for pricing, this was actually a board I had purchased for my own collection, and therefore didn't mock up a quote. However, if this were a customers board, this repair cost would have been substantial. Probably somewhere in the $500-600 range for everything. This board is worth well over a thousand dollars in good condition, so it would have been worth it anyway.